By 2018, global electricity demand was about 20,000TWh. Information and Communication Technology (ICT) industry accounted for 2000TWh or 10% of global electricity, two main portions of which were networks (wireless and wired) and Data centers. Dat...

Share

By 2018, global electricity demand was about 20,000TWh. Information and Communication Technology (ICT) industry accounted for 2000TWh or 10% of global electricity, two main portions of which were networks (wireless and wired) and Data centers. Data centers alone consume around 200TWh each year. Widely cited forecasts suggest that the total electricity demand of ICT will accelerate in 2020s, and that data centers will take a larger slice. The demand acceleration is driven by exponential data grows and 5G applications.

Data centers are the “brains” of the internet. Their role is to process, store, and communicate the data behind the myriad information services we rely upon every day, whether it be streaming video, email, social media, phone calls, or scientific computing. Data centers utilize different ICT devices to provide these services, all of which are powered by electricity. Servers, the key ICT components, provide computations and logic in response to information requests. Network devices, including wired Ethernet and wireless base stations, connect the data center to the internet and end users, enabling incoming and outgoing data flows. The electricity used by these IT devices is ultimately converted into heat, which must be removed from the data center by cooling equipment that also runs on electricity. Every point of power efficiency improvement impacts significantly not just no operation cost but on carbon footprints also.

Before reaching end components, all power needs to be processed by frond-end rectifiers. Currently, the efficiency of server and telecom power systems is mostly improved at this rectifier level. The rectifier efficiency of mainstream vendors is 90% to 96%. 98% rectifier efficiency solution has been proved to be achieved, but its application is still limited by the availability and cost of wide bandgape devices and control ICs. Besides efficiency, rectifier’s power density is also a key design requirement for data centers. Higher rectifier power density would free up more space for server capacity installation.

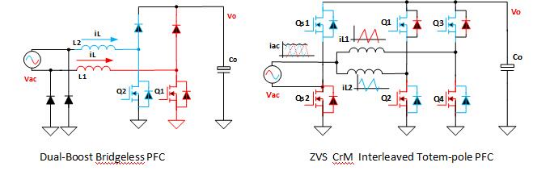

Rectifiers consist of a pre-regulator Power Factor Collection (PFC) stage and an isolated DC/DC converter. To achieve 98% rectifier efficiency, both PFC and DC/DC need to operate at 99% efficiency level. Traditional PFC with about 97.5% peak efficiency is not suitable for such designs anymore. Bridgeless PFCs become the only option for the new generation rectifier design. Currently two different bridgeless PFCs topologies, as shown below, are in products.

Double-Boost PFC is essentially composing of two boost converter. One operates at positive AC cycles and the other operates at negative AC cycles. It reduces semiconductor device number in power processing paths to 2 from traditional PFC’s 3, and as such the efficiency is improved. The advantage of this topology is simple control. Traditional PFC controllers can be used with some minor circuit modification. The drawback is that two boost inductors are needed, which would increase BOM cost and impact power density improvement. A single-phase CrM ( Critical Mode) PFC has a very limited ( < 500W) power handling capability due to the high boost inductor current ripple and difficulty of EMI filter design. ZVS CrM PFCs with over 500W power often use two phases interleaving. By offsetting the two phases’ switching period by 180 degrees, the current ripples can cancel each other and the total current ripple can be reduced to an acceptable range.

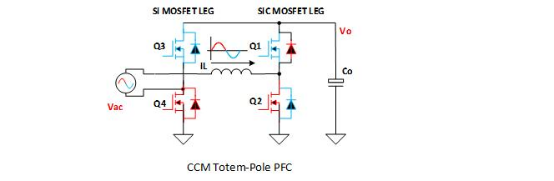

With the mature and cost reduction of SiC and GaN, rectifier design can employ more advanced and simpler topologies to achieve 96+% efficiency and operate at higher switching frequencies. The following is CCM (Continuous Conduction Mode) totem-pole PFC, which is well suitable for kWs’ rectifier design.

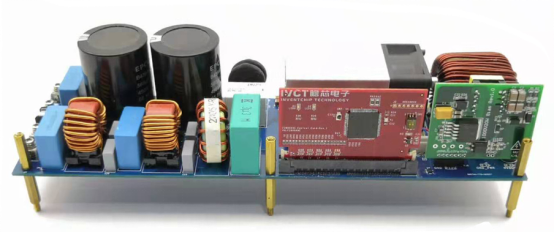

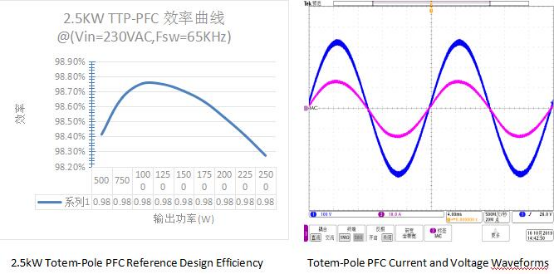

IVCT has developed a 2.5kW totem-pole PFC reference design. The following are the reference design photo and key test data. ( link to Application Note)

2.5kW Totem-Pole PFC Reference Design

For DC/DC stages, half-bridge and full-bridge LLC topologies are becoming very popular. There are two main reasons to make industry shift from the phase-shifted full bridge topology, which was a dominant topology in high power design, to the LLC topology. Full load range primary ZVS and wide load range secondary ZCS is the main merit of this topology. With no inductor on secondary side, a 12V or 48V server / telecom output makes it possible to use synchronous rectification circuit and cut down conduction loss significantly. The advantages enable LLC converters’ 99+% efficiency design. Due to LLC converters’ high output current ripple, for high current output designs, interleaved LLC structure is often used to reduce output voltage ripple and mitigate output filter capacitor self-heating.