Silicon Carbide Schottky Barrier Diodes (SiC SBD) are a very diverse type of diode, used everywhere that silicon rectifiers can be found. There are a number of key considerations when it comes to choosing the right SiC SBD for your design, & this blog discusses them. To help guide you, it is important that we explore further these essential factors for when a product lives on your body.

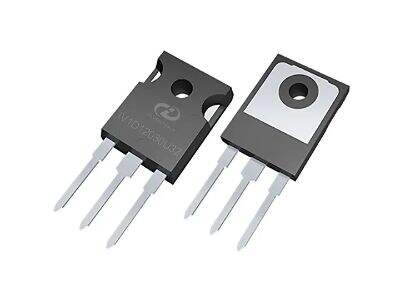

While the voltage level of a SiC SBD, indicates that up to what maximum Voltage it can withstand. For an optimal operational performance, you will need to choose a SiC SBD with correct voltage rating based on your own specific application needs. If something like this happened to our circuit, it would be torn apart as can seen in the picture below which goes on to show why we need such a heavy duty component for use!

Maximum Forward Current : This parameter is called the current carrying capacity of a Diode. Since the operation of some circuits requires large current flow which is what happens in this circuit and therefore better for SiC SBD to have a high IFSM.

Temperature Rating: The temperature rating of a SiC SBD is utmost important especially in high-temperature conditions. Selecting a high temperature rating SiC SBD that is suitable for the application to ensure optimal performance and no damage will occur on photovoltaic activities.

Leakage Current:- Leakage current is the remaining flow of charge through the diode when it remains in non-conduction state. High levels of leakage current result in energy wastage and inefficiencies within the circuit. Thus, it is necessary to choose a SiC SBD with low leakage current for best performance.

Here are some tips to help you evaluate the many SiC SBD options on the market.

Read the Datasheet: The datasheet of Silicon carbide Schottky barrier diode has all details such as voltage rating, current carrying capacity, temperature limit and leakage current etc. It is better to compare datasheets of different manufacturers in order to choose the most applicable option for your project.

Application considerationThis SI value may vary depending on the application of SiC SBD. Therefore, it is important to evaluate your project requirements and choose an appropriate diode carefully.

Manufacturer Note all the makers create similar caliber SiC SBDs. But make sure that manufacturer has demonstrated results and best-in-class performance in providing its set of excellent SiC SBDs.

Reviews: Browsing online reviews for a specific SiC SBD device you are considering can be a great way to gain insight as to what kind of quality and performance characteristics it has. You can be helped by feedback from other customers in making a well-informed choice.

Armed with the critical factors above and using all guidelines laid out, you should be able to comfortably select best matching SiC SBD for your project resulting in maximum performance & efficiency.