Across the power electronic landscape, a bit of an under-the-radar shift is occurring in response to three key technological advances: Silicon Carbide MOSFETs (SiC), Schottky Barrier Diodes (SBD) and very evolved gate-driver circuits. It has the potential to become a new championing alliance, revolutionising efficiency, reliability and sustainability as we know it down an avenue of power conversion flipped on its head. At the center of this change resides cooperation among these parts, that collaborated to drive power systems into a brand-new energy age.

SiC MOSFETs and SBD for the Future Power Electronics

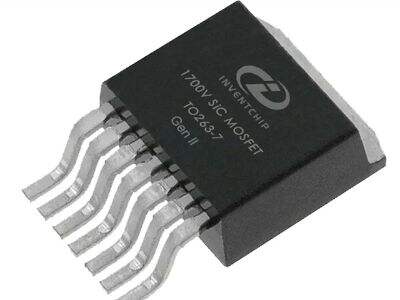

Due to these exceptional properties such as high thermal conductivity, low switching losses and operation at much higher temperatures and voltages than traditional silicon-based material it has become the foundation for a revolution in modern power electronics. Specifically, SiC MOSFETs allow higher switching frequencies resulting in significantly decreased conduction and switching losses as compared to an alternative using silicon. In tandem with SiC SBDs, which offer unprecedented ultra-low forward voltage drops and near-zero reverse recovery losses, these devices are ushering in a new era of applications - from data centers to electric aircraft. They set new standards for the industry by challenging tried, tested and true performance boundaries enabling smaller / lighter weight higher efficiency power systems.

Best Combination of SiC Devices and Modern Gate-Drivers

Advanced gate-driving greatly facilitates in fully exploiting the potential of SiC MOSFETs and SBDs. SiC itself would be appropriate, and these assessors are exacting at the speed of operation for best switching conditions granted to using LS-SiC devices. They make EMI a lot lower, by reducing gate ringing and controlling rise/fall times much better. In addition, these drivers typically include protection functions for overcurrent (OC), OC and short-circuit safe operation area(SCSOA) robustness but also against voltage faults like under-voltage lockout(UVLO), to protect the SiC devices in case of unwanted events. Such harmonious integration ensures not only optimized system performance but also a long life of SiC devices.

Next-Gen Power Modules: Energy Savings and Reduced Carbon Footprint

The main driver for using SiC-based power modules is the potential of large energy saving and carbon footprint reduction. Since SiC devices can operate at higher efficiencies, they consequently help reduce power consumption and waste heat generation. This can lead to huge reductions in energy bills and GHG emissions on large scale industrial as well renewable energy systems. A great example of this is the extended driving distance that can be achieved on a single charge with electric vehicles (EVs) utilizing SiC technology, and the increased power output and reduced cooling requirements for solar inverters. That makes SiC involved systems essentials for the world transition towards a cleaner sustainable future.

SiC in Collaboration: Getting More Reliability Out of the System

Any power electronics application requires high reliability and the combination of SiC MOSFETs, SBDs with advanced gate-drivers helps to a great extent in case of reliability. The intrinsic robustness of SiC against thermal and electrical stress guarantees performance uniformity even at the most extreme use cases. In addition, SiC devices enable reduced thermal cycling and lower operating temperatures reducing impact of temperature stress on other system components which will increase the overall reliability. Additionally, this ruggedness is strengthened when considering defense mechanisms built into contemporary gate-drivers as a means of comprehensive reliability engineering. And with total immunity to shock, vibration and temperature change SiC-based systems can operate in harsh environments for years at a time - which also means much longer maintenance intervals compared to silicon will translate into less downtime.

Why SiC is Key to Electric Vehicles and Renewable Energy

Leading the SiC charge fuels are EVs and renewable energy systems, both sectors ripe for runaway expansion. SiC power modules enable EVs to charge faster, drive further and more efficiently thus help mass-market adoption of electric mobility. SiC technology helps to improve vehicle dynamics and increase passenger space by reducing the size & weight of power electronics. SiC devices are also central to the renewables energy realm through enabling improved efficiency in solar inverters, wind turbine converters and energy storage systems. These power electronics can enable the grid integration and optimize supply of renewable sources by stabilizing system frequency and voltage response (due to their capability in handling higher voltages, currents with lower losses), thus contributing significantly for a better dual benefit mix.

To sum up, this SiC MOSFETs + SBDs package with the advanced gate-drivers is one of examples that showcase simply how synergies can change a whole view on many things! This triad with limitless efficiency technological advantage, affordable layers of reliability and deep-rich green scientific-based sustainability are not only inspiring the future wave in power electronics but also pushing us to our more energy-efficient clean world. As these technologies further develop through research and development activities, we are on the verge of a new SiC age.

EN

EN

AR

AR

HR

HR

DA

DA

NL

NL

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

IW

IW

ID

ID

LT

LT

SR

SR

SK

SK

UK

UK

VI

VI

SQ

SQ

HU

HU

TH

TH

TR

TR

FA

FA

AF

AF

MS

MS

HY

HY

BN

BN

LA

LA

TA

TA

TE

TE

MY

MY