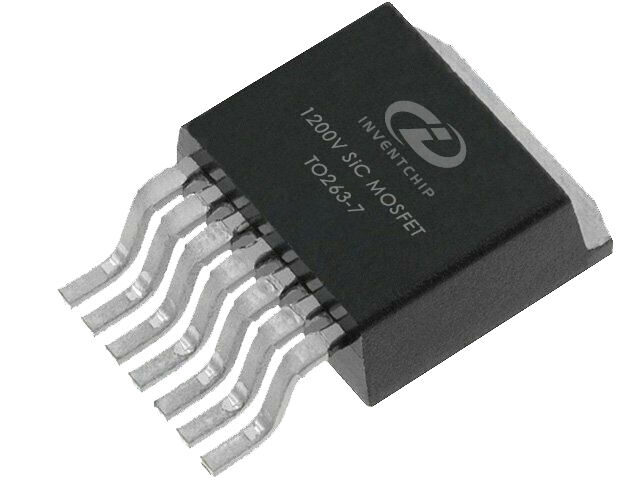

Використовуються у різних застосуваннях у виробничості, авіаційній промисловості та галузі ЕВ, серед інших; SiC MOSFET або металево-оксидні напівпровідникові транзистори на основі кремнія-карбіду, як повністю відомі ці нові пристрої. Ці незвичайні пристрої є великою кроком вперед у порівнянні з традиційними силиконовими MOSFET і відіграють ключову роль у багатьох технологіях, включаючи системи зв'язку (бекгал), управління енергією ЕВ та застосування сонячної системи.

Вибір правильного SiC MOSFET вимагає як основної розуміння, так і докладного розгляду різних ключових показників. Зрозуміння вимог застосування для вашого проекту допоможе вам вибрати ідеальний SiC MOSFET та оптимізувати продуктивність та тривалість.

Саме тому переваги SiC MOSFET так привабливі у багатьох інших застосуваннях. Ці преміальні компоненти мають одну з найвищих ефективностей на ринку, що дозволяє їм працювати з великою силою струму з меншими витратами енергії та генерацією тепла. Крім того, вони мають дуже швидкі часи комутації (приблизно в 1000 разів швидше, ніж традиційні силіконові MOSFET), що дозволяє їм увімкнутися та вимкнутися майже моментально. І, у випадку використання при температурі нижче нуля, SiC MOSFET є надійними - перевага, яку важко досягти за допомогою стандартних силіконових компонентів.

Транзистори SiC MOSFET роблять великий крок уперед у електронній інновації та безпеці, надаючи кращі технологічні функції, а також передові міри безпеки. Їхньої міцна побудова та збірка значно сприяє запобіганню перегріву систем або їх неправильного використання, особливо в високопродуктивних промислових застосуваннях та автомобільній промисловості, де надійність є ключовим фактором.

Транзистори SiC MOSFET використовуються у багатьох галузях та промисловостях, включаючи, але не обмежуючись, автомобільною промисловістю. Ці властивості є важливими у багатьох областях, таких як керування двигунами, сонячні інвертори та системи приводу електромобілів для підвищення ефективності застосування. Навіть у разі домінування силіцію в технологічному просторі електромобілів, головним чином завдяки його ефективності та здатності зберігати вагу, транзистори SiC MOSFET швидко замінюють традиційні напівпровідникові транзистори (IGBT) у сонячних інверторах та компонентах приводу завдяки своєму стійкому потужному управлінню при змінних енергетичних конвертаційних динаміках.

Інженери-конструктори повинні розуміти експлуатаційні характеристики SiC MOSFET для максимальної використовування його переваг у вигляді продуктивності. Ці пристрої схожі на традиційні Металево-оксидні напівпровідникові транзистори (MOSFET), але мають надзвичайно високі номінальні значення напруги, швидке комутаційне переключення та здатність обробки навантажень. Для функціонування з максимальною потужністю компоненти повинні працювати всередині своїх специфікованих номінальних значень напруги щодо швидкості переключення та термального управління, щоб уникнути перегріву, який може призвести до виходу компонента з ладу.

Крім того, вибір добре відомої марки з відмінним сервісом та якісною продукцією може ще більше покращити досвід користувача, пов'язаний з SiC MOSFET. Особливий акцент на безплатних пробах для валідації та пожизненній підтримці після продажу допомагає у виборі правильного виробника. Оскільки SiC MOSFET можуть витримувати більш тверді умови, одночасно забезпечуючи відмінну продуктивність, вони теж тривають довше і забезпечують більшу надійність у електронних системах.

Транзистори на основі SiC є незамінними у широкому діапазоні електронних застосувань, де потрібна висока продуктивність та ефективність. Вибір правильного транзистора на основі SiC включає відповідність напругових характеристик, швидкості комутації, здатності до обробки струму та теплового управління для забезпечення ідеальної продуктивності разом з міцністю. Об'єднавши ключові фактори з надійним джерелом та розробляючи системи, які добре поєднуються з власними властивостями транзисторів на основі SiC, можна досягти небувалого рівня продуктивності електронних систем на багато років вперед. Ураховуючи ці розгляди тощо, можна обрати відповідний транзистор на основі SiC, щоб задовольнити поточні потреби та, в кінцевому рахунку, забезпечити перевагу у надійності та прибутку в продуктивності для електронної системи у майбутньому.

EN

EN

AR

AR

HR

HR

DA

DA

NL

NL

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

IW

IW

ID

ID

LT

LT

SR

SR

SK

SK

UK

UK

VI

VI

SQ

SQ

HU

HU

TH

TH

TR

TR

FA

FA

AF

AF

MS

MS

HY

HY

BN

BN

LA

LA

TA

TA

TE

TE

MY

MY