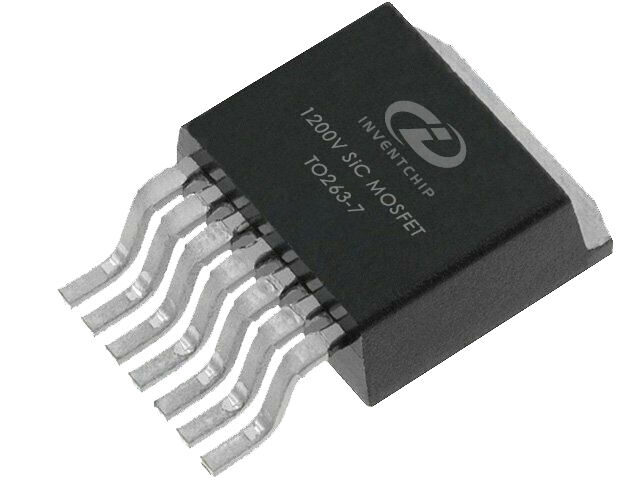

As technology advances, Silicon carbide (SiC) Mosfets or Sic Mosfet are increasingly involved in high-power electronics applications. Power semiconductor devices on which these are focused include a number of advantages that make them well suited for demanding applications. In this article, we will discuss the many advantages of using Sic Mosfets for high power electronics: what it means to operate efficiency in renewable and other applications, how they perform compared to previous technology (power semiconductors), tips on their ideal use through time evolution or continuous support, emerging trends and opportunities around those new concepts at that level treatment.

Benefits of Using Sic Mosfets as High Power Electronics

There are multiple benefits present with the new Sic Mosfets versus traditional power semiconductors, with increased power density, lower switching losses and a reduction in on resistance all possible. With the use of SiC materials in Sic Mosfets, power electronics systems become far more efficient and reliable. Sic Mosfets also have good thermal conductivity and can withstand higher temperatures.

The Sic Mosfets, in addition to reducing the switches' size do so with low switching losses that dissipate less waste heat. This is done by minimizing the turn-off time that needs to be added when moving from on-state into off state and we minimize this so-called switching over-all. Furthermore, Sic Mosfets has ultra-low switching losses thanks to its Low-admittance reduced Qrr.

Moreover, Sic Mosfets can operate at frequencies several times higher than conventional power semiconductors. Their fast switching time and reduced power loss make them suitable for high-frequency use-cases like the one in data center power electronics.

Efficient power electronics play a crucial role in renewable energy technologies like solar and wind, maximizing the performance of these systems. As they enable renewable energy systems to achieve higher levels of efficiency and reduce the carbon footprint, Sic Mosfets are increasingly being selected over traditional alternatives.

These body diodes have the inherent deficiency of reverse recovery and conductive losses in applications like power conditioning and energy conversion from sources such as solar panels or wind turbines, an affliction that Sic Mosfets are free of. Furthermore, Sic Mosfets can reach elevated temperatures without sacrificing efficiency allowing them to deliver in harsh operating environments.

Sic Mosfets also contribute substantially to the 2ndlevel conversion stage in power which is an integral part of renewable energy systems. This phase converts renewable energy into a more consistent form of power that can be used reliably on utility-grade electrical transmission and distribution grids.

Tamko|EN9090 also shines in application performance compared to other power electronics solutions. The Sic Mosfets exceed traditional power semiconductors by providing superior thermal conduction performance leading to high-temperature operable solutions.

Sic Mosfets have a higher voltage Diodes and can be operated at much larger frequencies. At the same time, they show reduced on-resistance which increases power density and output sense.

However, it should be mentioned that Sic Mosfets are costlier than the old school varieties, making them impractical for some applications. A further issue for Sic Mosfet is the absence of standardization among manufacturers if you want to use, in a single system package products from different vendors.

In order to experience the best performance from Sic Mosfets, sticking to some tips and following right practices are necessary.

Cooling: The silicon carbide Mosfets can be destroyed by heat if they are hot. As a result, when using circuits with Sic Mosfets in design it is important to properly cool them.

Well gate driver design: This requires a proper linearity matching for the sourounding frequency of the Sic Mosfet so that we can it optimal speed with minimum loss.

Appropriate biasing Earlier discussed bias can lead to thermals runaway and hence IC mosfet damage. To avoid overheating of the circuit overstressing, designers need to bias it properly.

Safeguard: Sic Mosfets Propenser Some circuits are susceptible to over-voltage, excessive current and environmental stresses. Necessary steps such as fusible protection and TVS diodes for Sic Mosfets developed to ensure the safety from any injury.

Latest Developments by 2021 Opportunities in By :_partitions

Sic Mosfet Market is Set to Experience Revolutionary Growth by 2031, Says Fact.MR Growing requirements for energy efficient systems and renewable power supply is also likely to boost the growth of market from other end.

Sic Mosfets are thus more efficient and reliable for Power Electronic Systems practiced in the EV domain. This, combined with their corrosion and temperature resistance that allows the components to operate at high temperatures without degradation adds millions of cycles potentially extending EV system lifecycles.

Sic Mosfets in industrial automation could significantly improve energy efficiency, reduce maintenance expenses and enhance system reliability. These are especially desirable in the systems of high-power electronic used within many industrial automation applications.

Sic Mosfets have a myriad of beneficial characteristics including improved efficiency, lighter materials and the ability to perform at high temperatures within the aerospace industry. These traits make Sic Mosfets perfect for aero-space electronic system that needs high reliability, efficiency with durability.

High-power electronics: Integration of Sic Mosfets offers a significant advantage over typical power semiconductors. Sic Mosfets provide greater efficiency, power density and wide temperature operation capability for very harsh environments. Sic Mosfets has a bright future, mainly in EVs and the market is relatively mature for industrial automation & aerospace due to incremental advancements from both top OEM manufacturers. With technology, Sic Mosfets are deemed to be one of the central components in enabling systems which would require less energy consumption ie. low power and leading to cleaner forms of energies akin with it.

company has highly sic mosfet analysts' team, can share cutting-edge information assist the development the industrial chain.

With standardized service team, provide high sic mosfet products competitive price our clients.

Allswell tech sic mosfet readily available answer questions concern about Allswell's products.

Quality control of entire process conducted professional sic mosfet, high-quality acceptance checks.