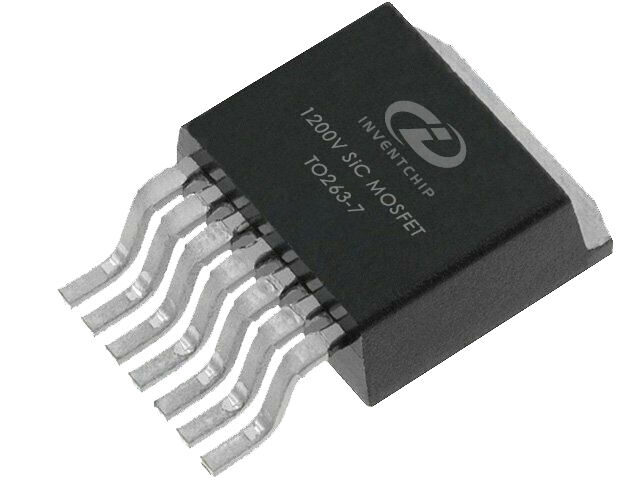

Power electronics is always seeking for more efficient technology and believe me, this power system world never get enough. A BIC 1200 Volt SiC MOSFET has opened up what is arguably the most revolutionary development in power electronic.There are many such counterexamples. Advantages of these new SiC MOSFETs compared to conventional silicon-based (Si) IGBT/MOS based switches, include higher voltage ratings; faster switching and lower switching losses.

As already mentioned, the primary benefit of 1200V SiC MOSFETs vs. traditional silicon (Si) is its higher voltage capabilities These new MOSFETs can handle voltages up to 1200V, which is much higher than the conventional limit of about 600V for silicon MOSFETs and so-called superjunction devices. This is a characteristic relevant for high-voltage applications like EVs, renewable energy systems, and industrial power supplies.

1200V SiC MOSFETs have higher voltage capabilities and faster switching speeds. This allows them to switch on and off much faster, which equals greater efficiency as well as lower power losses. Furthermore, SiC MOSFETs have a lower on-resistance than silicon-based power FET's which also helps reduce the efficiency of DC/AC conversion.

1200V SiC MOSFETs offer a higher voltage and faster switching speeds which make them ideal for most applications. SiC MOSFETs can be used in electric vehicles to enhance the efficiency and performance of power electronics for such motor driven applications. SiC MOSFETs switching speed is faster they can also find application on industrial motor drives and power supplies where the half-bridge inverter excessive heat may be a challenge.

One segment in which SiC MOSFETs are finding their way is renewable energy systems. As an example, SiC MOSFETs in solar energy systems have the potential to enable higher power density and longer lifetime for inverters that convert DC power of the solar panels into AC grid. Due to the higher voltage capabilities of SiC MOSFETs, they are ideal for this application because solar panels generate high voltages and traditional silicon MOSFETs struggle with that.

Advantages of 1200V SiC MOSFETs for use in High-Temperature Environment

Above all, SiC MOSFETs can also work at high temperatures. Silicon MOSFETs, on the other hand, are largely inefficient at high temperatures and can overheat to stop functioning. In contrast to silicon MOSFETs, SiC MOSFET can operate at up to 175°C which is an higher than the maximum temperature for a most commonly used motor power insulation class.

This high thermal ability could be a paradigm shift in industrial use-cases. For instance, SiC MOSFETs can be employed to adjust the speed and torque of a motor in motor drives. In a high temperature environment in which the motor is operating, SiC MOSFETs can be more efficient and reliable than traditional silicon-based MOSFETs.

Renewable energy systems is a particularly large and growing area for the impact of 1200V SiC MOSFETs. The world as momentum is onto renewable power sources in the form of solar or wind and this has increased the need to achieve good, efficient Power electronics.

The use of SiC MOSFETs can also solve a lot of ordinary business problems with renewable energy systems. As an example, they can be used in the inverter to convert DC power from solar panels into AC power for the grid. The SiC MOSFETs make conversion more advantageous, which means that the inverter is able to operate with a higher efficiency and less power loss.

SiC MOSFETs can also assist in tackling a few other problems associated with grid integration of renewable energy systems. For instance, if a large increase is created by solar or wind power digitally de-modifying how much the network can load. Grid-Connected Inverters: SiC MOSFET used in grid-connected inverters enable active control of reactive power, contributing to grid stabilisation and a reliable delivery of energy.

Unlock the Power of 1200V SiC MOSFETs in Modern Electronics

MOSFETs rely on silicon carbide and its wide bandgap properties to work at far higher temperatures, frequencies, and voltages than their simpler silicon predecessors. This 1200V rating is particularly important for high-power conversion applications like electric vehicles (EVs), photovoltaicutl inverters, and industrial motor drives. SiC MOSFETs reduce the switching losses and conduction losses, allowing for a new realm of efficiency that in turn allows smaller cooling systems, lower power consumption while providing cost savings over time.

Solar PV and wind turbine-based renewable energy systems integrated into the grid are sensitive to changes in voltage, current frequency etc., also requiring components that can withstand low efficiency inherent with fluctuations of input power. 1200V SiC MOSFETs achieve this by boasting faster switching frequencies, delivering better control of power conversion. Which not only translates to greater overall system efficiency but also improved grid stability and integration capabilities, playing a significant role in pushing for an eco-friendlier more sustainable energy deployment landscape.

Longest Range and Faster Charging enabled by 1200V SiC MOSFET Technology [English]init (1)

Those are the magic words in the electric vehicle (EV) industry, where house brands and cutting-edge design exist primarily to feed a high priority on achieving both longer ranges than rivals as well as faster charging times. Cree's 1200V SiC MOSFETs save space and weight in EV powertrains when installed into onboard chargers and drive systems. Their higher temperature operation reduces cooling requirements, which opens space and weight for more batteries or improves vehicle design. In addition, the increased efficiency facilitates range extension and faster charging times-two key factors in consumer adoption of EVs that will hasten their global proliferation.

Solving the Challenge of High Temps in Smaller and More Reliable Systems

Thermal management and space constraints are real pitfalls in many high-performance electronic systems. Since the 1200V SiC MOSFET is so resistant to higher temperatures, this means that cooling systems can also be reduced in size as well as packaging and without any loss of reliability. SiC MOSFETs play a critical role in industries such as aerospace, oil and gas exploration, heavy machinery, where operating conditions are demanding and space is limited for smaller footprints to less weight offering resilience during harsh environment reducing maintenance efforts.

Wide Ranging Uses of Silicon Carbide MOSFETs at 1200 V

But the applications of 1200V SiC MOSFETs extend far beyond renewable energy and electric mobility. They are used in the development of high-frequency DC/DC converters for data centers and telecommunications equipment to provide energy efficiency, power density etc. They help to miniaturize imaging systems and surgical tools in medical devices. SiC technology is powering chargers and adapters in consumer electronics, resulting in smaller, cooler-running and more efficient devices. With continued research and development, the applications for these advanced materials should seem virtually limitless.

professional analysts team, they can share cutting-edge knowledge help the 1200v sic mosfet of industrial chain.

Quality control of entire process conducted professional 1200v sic mosfet, high-quality acceptance checks.

Allswell Tech support there 1200v sic mosfet any concerns questions about Allswell's products.

provide our clients with best high-quality products services at 1200v sic mosfet affordable cost.

To sum up, the emergence of 1200V SiC MOSFETs is a game-changer in power electronics and leads to unprecedented efficacy, reliability and miniaturized system. Their applications are wide-spread, ranging from green power revolution to automotive industry and cutting-edge technological advancements for example. This bodes well for a future of silicon carbide (SiC) MOSFET technology that will continue to push boundaries, and its use being truly transformative as we look 50 years ahead at the world from hereapatkan/